The article Batteries for electric cars – made from dirty coal! Researchers make discovery by Felix Baumann appeared first on BASIC thinking. You can always stay up to date with our newsletter.

Researchers at Oak Ridge National Laboratory have discovered a way to convert the dirty fuel coal into graphite. Their method could help develop more sustainable batteries for electric cars.

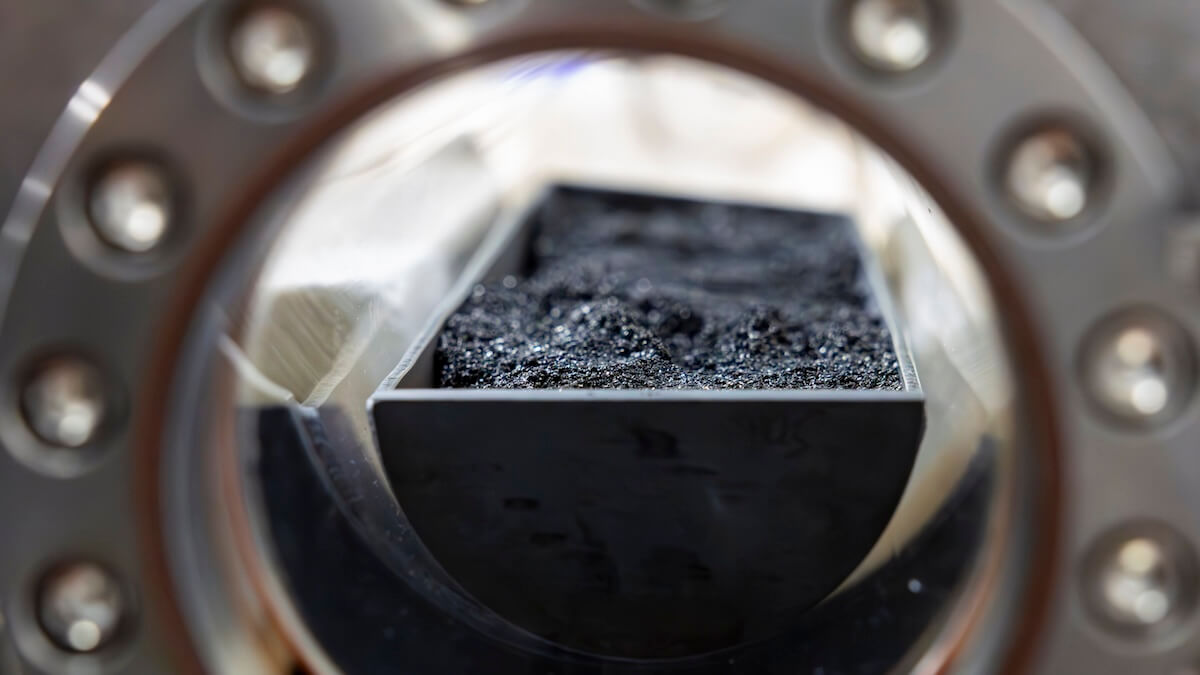

Coal is considered a symbol of environmental pollution. But it could soon play a positive role in the energy transition. Because scientists at the Oak Ridge National Laboratory (ORNL) in the USA have a method designed to convert coal into graphite. The material is essential for the production of batteries for electric cars and for storing renewable energy.

Graphite is considered a “critical raw material” because it is only available in limited quantities in many parts of the world and is heavily dependent on imports. Coal, on the other hand, is plentiful and relatively cheap. ORNL’s new method relies on a combination of chemical and electrochemical processes to turn coal waste into high-quality graphite.

A machine heats the coal without oxygen, which means there are no emissions. She then transforms them into graphite in a reactor. This process not only saves costs, but also uses waste from old coal mines.

Carbon batteries as an environmentally friendly alternative

The new technology is said to have several advantages. It supports the production of high-performance batteries, reduces dependence on imports and offers economic prospects for former coal mining areas. The recycling of coal waste in particular is a major step forward: it creates benefits from residual materials and at the same time contributes to environmental cleanup.

According to the researchers, batteries using this graphite could perform similarly to commercial batteries – but be manufactured at a lower cost. This is intended to reduce energy consumption, as the production temperature for the graphite is only around 815 degrees Celsius – significantly lower than with conventional processes.

On the way to commercialization

The researchers are already working on scaling the process for industrial applications. Initial analyzes show that the costs of the new method are up to 13 percent lower than those of conventional methods. Companies like Ramaco Carbon, a partner in the project, plan to put the technology into practice by setting up pilot plants.

In the long term, these developments could not only change the graphite market, but also create jobs in former coal mining areas. The goal is to produce not only graphite but also batteries locally and thus make the entire value chain sustainable.

Also interesting:

- Diamond battery made from nuclear waste will power devices for thousands of years

- Graphite trick: New electric car battery can be charged in 15 minutes

- Heat battery: Electric stones heat air or gas to almost 2,000 degrees

- Lithium alternative: How do sodium-ion batteries work?

The article Batteries for electric cars – made from dirty coal! Researchers make discovery by Felix Baumann appeared first on BASIC thinking. Follow us too Google News and Flipboard.

As a Tech Industry expert, I have mixed feelings about the idea of using batteries for electric cars made from dirty coal. On one hand, it is concerning that using coal to power the production of batteries could contribute to further environmental degradation and exacerbate climate change. Coal is a highly polluting energy source with significant carbon emissions, and using it to produce batteries could undermine the overall goal of reducing greenhouse gas emissions through the adoption of electric vehicles.

However, on the other hand, I recognize that technological advancements and research discoveries in the field of battery production could potentially mitigate the negative environmental impacts of using coal. If researchers are able to develop more efficient and sustainable processes for producing batteries using coal, it could help to make electric vehicles more accessible and affordable for consumers, ultimately accelerating the transition away from fossil fuel-powered vehicles.

Ultimately, as a Tech Industry expert, I believe it is important to continue to monitor and evaluate the environmental impact of using coal for battery production, while also supporting and investing in research and development efforts to improve the sustainability of battery manufacturing processes. It will be crucial for industry stakeholders to work together to find innovative solutions that prioritize both environmental sustainability and technological advancement in the transition to electric vehicles.

Credits