The contribution battery revolution? Tin foam reduced loading stress of batteries first appeared at the online magazine Basic Thinking. You can start the day well every morning via our newsletter update.

Tin is cheaper than many other metals-and could still significantly improve the performance of lithium-ion batteries. This is made possible by a microporous tin foam that cushioned mechanical stress better when charging.

As part of the energy and mobility turnaround, the demand for reliable technologies increases. Batteries with a special property play an increasingly important role. While lithium-ion batteries are often sufficient for mobile devices, the quick loading and unloading in electricity storage is death for this technology.

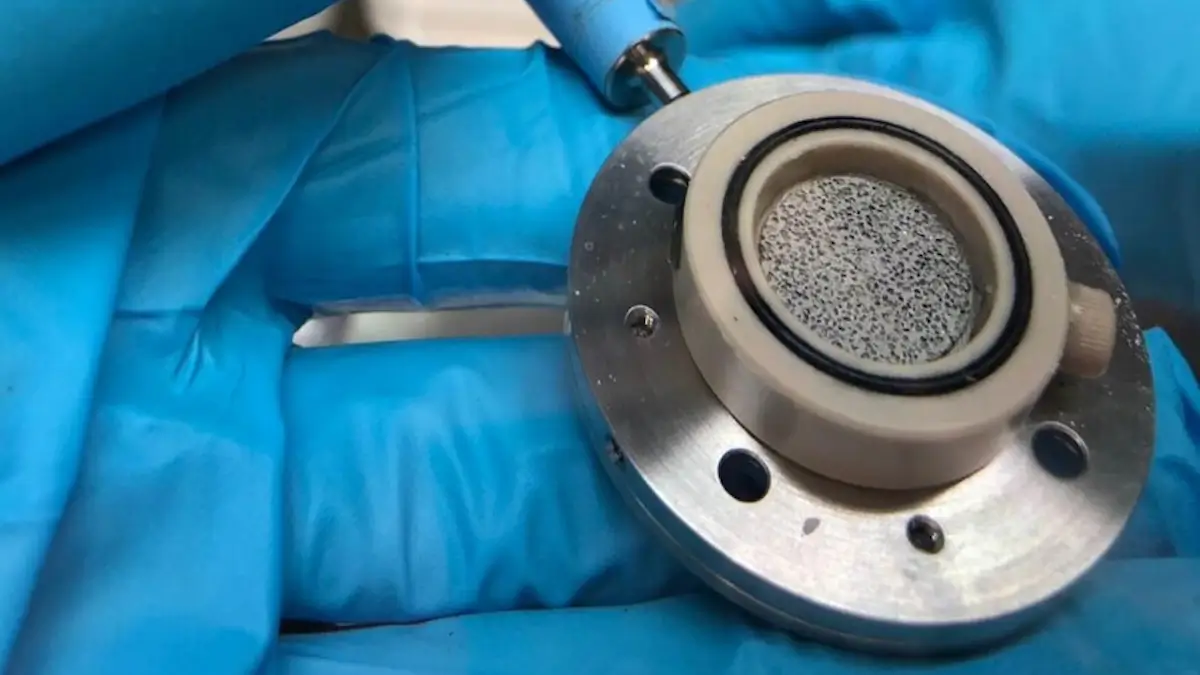

Researchers of the Helmholtz Center However, have recently presented another promising solution. It is an electrode made of tin foam.

Other metal-based materials for electrodes of lithium-ion batteries, for example, ensure that they expand heavily when storing lithium. This can lead to structural damage and a lower capacity in the medium term. Tin foam should be able to solve this problem,

Tin foam battery can save three times more energy

Compared to graphite, Zinn can save about three times more energy. But so far the material has also to struggle with the problem to swell in the medium term if it absorbs too much lithium. Therefore, the researchers developed a highly pine tin foam with small pores. These are only a few micrometers in size, but they enable the material to easily expand like a sponge.

In the result, the foam can expand without breaking or deforming in the long term. Under an X-ray device, the researchers found that the tin foam is more stable than tin foils and at the same time a promising alternative compared to other materials. This could lead to better batteries in the future, whether for electric cars or smartphones.

Further optimizations possible

The researchers emphasize that the structuring of the tin is decisive. Therefore, the team continues to work to define the optimal structure for wider use. In addition, it is not entirely clear how a tin foam cuts off compared to other metals and there may be further optimization potential.

Nevertheless, the technology shows that battery research is still about to optimize existing technologies and material compositions. It should therefore not be long before industry and consumers have access to even better lithium-ion batteries.

Also interesting:

- Why e-cars on cargo ships are no greater danger

- Study: How artificial intelligence can become more sustainable

- Mobile air conditioning: You have to count on these electricity costs

- The most stubborn electric car myths-and what is about them

The contribution battery revolution? Tin foam reduced charging stress from batteries first appeared on basic thinking. Follow us too Google News and Flipboard Or subscribe to our update newsletter.

As a Tech Industry expert, I am excited about the potential of the battery revolution and the development of new materials like tin foam that can help reduce charging stress in batteries. This innovation has the potential to improve the performance and longevity of batteries, making them more efficient and reliable for a wide range of applications.

The use of tin foam in batteries could also lead to faster charging times and increased energy storage capacity, which would be a game-changer for electric vehicles, portable electronics, and renewable energy storage systems. Overall, the advancement of battery technology is crucial for the continued growth and success of the tech industry, and I look forward to seeing how these innovations will shape the future of energy storage.

Credits