The article how much CO2 caused the battery production for electric cars first appeared at the online magazine Basic Thinking. You can start the day well every morning via our newsletter update.

Electric cars start with a CO2 backpack from the battery production. A current white paper shows how high the emissions in electric car production are actually and how they can be reduced. An overview.

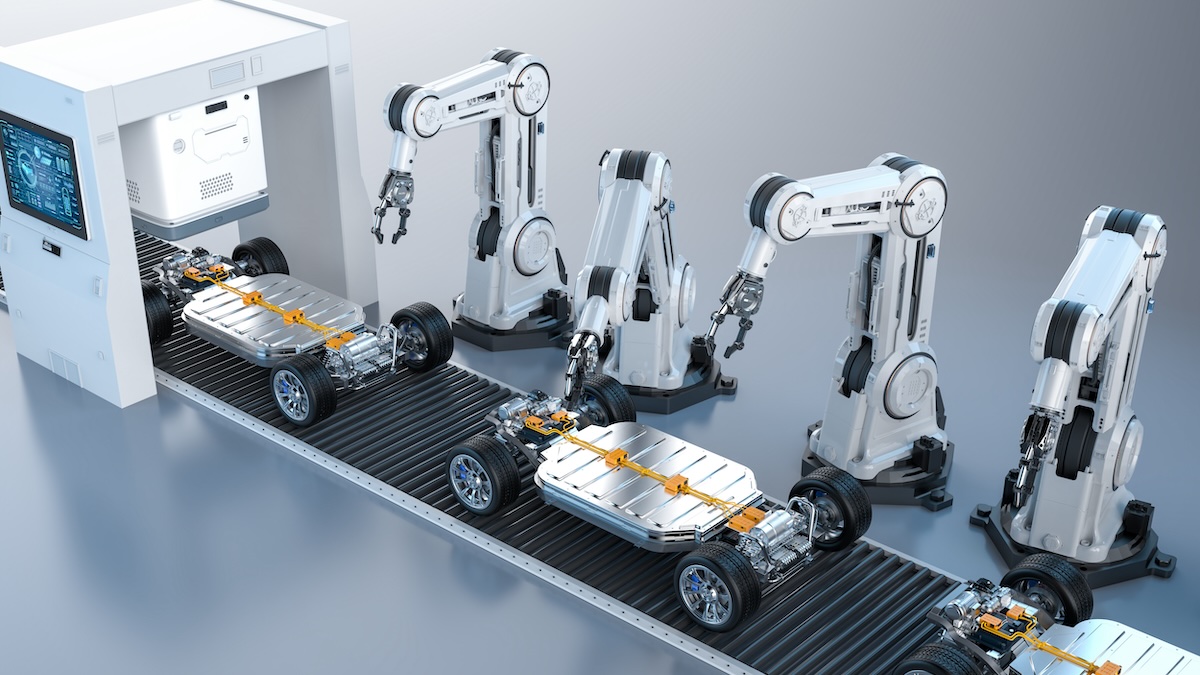

Electric cars are considered an important factor in the fight against climate change. While they cause significantly fewer emissions in operation than vehicles with combustion engine, their production is very energy -intensive, especially with regard to battery production.

CO2 emissions in battery production for electric cars

How much CO2 the battery production actually causes recently examined the company advice P3. A team of experts has analyzed the most important emission sources along the value chain and in one White paper published.

In connection with e-car production, the so-called “CO2 backpack” is often discussed. The term refers to the higher emissions that arise during battery production for electric cars.

The P3 team assumes that electric cars compensate for the CO2 load after a mileage of around 80,000 to 120,000 kilometers. If 100 percent green electricity is used, this route is reduced to around 40,000 to 70,000 kilometers.

How can emissions be reduced

The life cycle analysis of an e-car battery examines the entire process from raw material extraction to supply to recycling. It is based on a combination of primary data from factories and suppliers with secondary data from scientific databases.

Based on the knowledge gained in this way, the experts could not only find out at which points of battery production most emissions arise, but also how they can be reduced.

CO2 emissions in battery production are currently around 55 kilograms of CO₂ equivalents per kilowatt hour. With targeted improvements, it could drop to around 20 kilograms of CO₂ equivalent per kilowatt hour. This would improve the climate balance of e-cars after 30,000 to 50,000 kilometers.

Fewer CO2 emissions in battery production

One possibility is the choice of cathode material: Lithium-iron-phosphate cells need around 60 percent less energy in production than nickel-mangan cobalt cells.

And renewable energies are also a lever: if the processing and supply chain is completely based on clean electricity, the CO2 footprint drops by about a third. In cell production itself, too, savings can be achieved by automated large factories.

At the same time, the focus is on the production of the production facilities. The P3 team shows that the CO₂ footprint of a typical coating machine is 65 tons of CO₂. Recycling of secondary materials could be reduced by at least 30 percent.

An important key is also the recycling of the batteries. While traditional melting processes only get small amounts of material and cause high emissions, modern mechanical and hydrometallurgical processes offer significantly better results. In the future, even new direct recycling technologies could bring even more efficient solutions.

In summary, this means that electric cars start with a fairly heavy CO2 backpack. The CO2 footprint of battery production can be significantly reduced by optimized production, the use of clean energy and the sensible use of materials and recycling.

Also interesting:

- “Breathe” battery stores electricity and binds CO2

- 84 percent less CO2: Green nickel is supposed to drive energy transition forward

- E-car as an energy storage: Bidirectional shop is not a battery killer

- Batteries: AI discovers alternatives that could replace lithium

The article how much CO2 caused the battery production for electric cars first appeared on basic thinking. Follow us too Google News and Flipboard Or subscribe to our update newsletter.

As a Tech Industry expert, I believe it is important to acknowledge that the production of batteries for electric cars does contribute to CO2 emissions. While electric vehicles are generally considered to be more environmentally friendly than traditional gasoline-powered cars when considering their overall lifecycle emissions, the production of batteries does have an environmental impact.

The mining and processing of materials such as lithium, cobalt, and nickel for battery production can be energy-intensive and can result in CO2 emissions. Additionally, the manufacturing process itself, including the assembly of the battery cells, also requires energy and can contribute to emissions.

It is important for the industry to continue to innovate and improve battery production processes to minimize their environmental impact. This could include increasing the use of renewable energy sources in the production process, improving recycling and reuse of materials, and investing in more sustainable battery technologies.

Overall, while battery production for electric cars does have a carbon footprint, the benefits of transitioning to electric vehicles in terms of reducing overall emissions and combating climate change outweigh the environmental impact of battery production. It is crucial for the industry to continue to work towards more sustainable practices to minimize the carbon footprint of electric vehicles.

Credits