The article Researchers develop biodegradable circuit boards made of wood first appeared in the online magazine BASIC thinking. With our newsletter UPDATE you can start the day well informed every morning.

Swiss researchers have developed biodegradable printed circuit boards (PCBs) made of wood. The aim is to reduce electronic waste without sacrificing performance.

Every modern electronic device, from smartphones to electric toothbrushes, contains a printed circuit board, or PCB. These plates, which connect all the tiny components together, are largely made of non-recyclable plastics and contribute significantly to the over 50 million tons of e-waste worldwide every year.

Researcher at the Federal Laboratory for Materials Science and Technology (Empa) in Switzerland developed now a new type of circuit board made entirely of biodegradable materials.

Traditional PCBs are made from a mixture of glass fibers and a plastic (a fiber-reinforced petroleum-based epoxy resin). This combination makes the panels stable and resistant to heat, but also almost impossible to recycle.

Because: Separating the materials is complex and expensive, which is why most panels either end up in landfills or are burned. This wastes valuable raw materials such as gold and copper and releases pollutants.

Biodegradable wooden circuit board

The Empa researchers chose a new approach and used a particularly renewable natural raw material: wood. Wood consists of the plant molecules lignin and cellulose, which give it structure and strength. The researchers obtained so-called lignocellulose nanofibrils from the pulp, which is a waste product of biorefinery processes and is rich in lignin and cellulose.

The team ground these fibers with water to form a fine paste. The scientists then pressed the wet material under high pressure to remove the water. This caused the fibrils to condense into an even, smooth and solid plate, which serves as the basis for the new biodegradable circuit board.

Performance like conventional plates

Tests showed that the wood circuit board has almost the same rigidity, strength and ability to conduct heat and electricity as traditional epoxy resin boards. Additionally, the surface was smooth enough to print precise electronic circuits using inkjet technology.

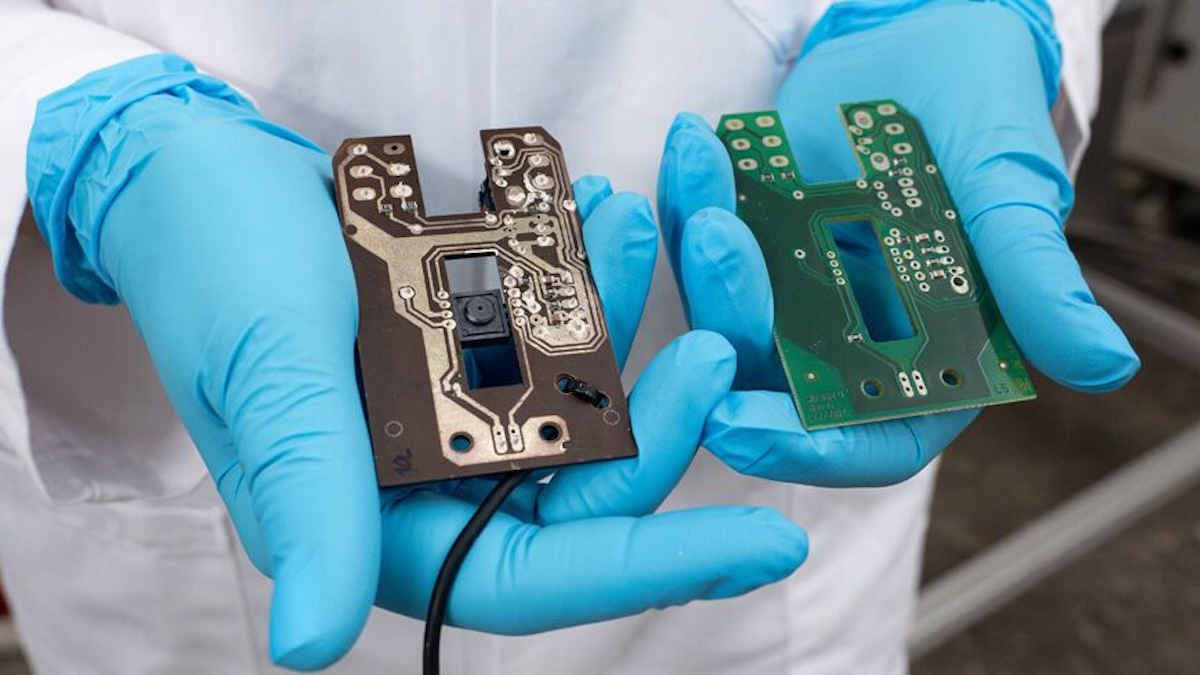

To prove its practical suitability, the researchers built a fully functional computer mouse. The housing consists of a combination of bioplastic and wood particles. The production was carried out using 3D printing.

The finished mouse functioned like a conventional device, but could be composted at the end of its life. However, the researchers noted that the new material is currently slightly less resistant to moisture than traditional PCBs, an important consideration for use in consumer devices.

The Empa team is already working on coatings and material adjustments to address this problem. Initial estimates suggest that manufacturing wood PCBs could reduce carbon emissions by more than half compared to epoxy resin boards.

Also interesting:

- ChatGPT Listening: Disable background conversations

- Solar implant with AI should enable blind people to read again

- Vertical wind turbine with AI – for houses in the city

- Electricity through steps: the future of sustainable energy?

The post Researchers develop biodegradable circuit boards – made of wood appeared first on BASIC thinking. Follow us too Google News and Flipboard or subscribe to our newsletter UPDATE.

As a Tech Industry expert, I find the development of biodegradable circuit boards made of wood to be a fascinating and innovative idea. This advancement has the potential to significantly reduce electronic waste and environmental impact associated with traditional circuit boards made of non-biodegradable materials like plastic and metal.

Using wood as a base material for circuit boards is not only eco-friendly but also sustainable, as wood is a renewable resource. Additionally, the biodegradability of these circuit boards means that they can be easily disposed of without causing harm to the environment.

However, there are likely to be challenges in terms of the performance and durability of wood-based circuit boards compared to traditional materials. Researchers will need to ensure that these biodegradable circuit boards meet the same standards of reliability and functionality as their non-biodegradable counterparts.

Overall, I believe that the development of biodegradable circuit boards made of wood represents a positive step towards creating more environmentally friendly and sustainable technology products. I look forward to seeing how this technology evolves and becomes more widely adopted in the tech industry.

Credits